Original IR 118

HighTech Curing With 118 Needles

Manufacturer: RUHLE

Condition: New

Superior brine distribution for chicken, pork, fish, beef, and other meats for increased shelf life and yield.

A versatile rotary pump – Built as an immersion pump, this apparatus is genuinely versatile. The pump works at low pulsation and is self-priming, dry-run safe and self- draining up to the last drop. The quick-suctioning geometry of the pump wheel enables air removal, thus improving the brine. Consequently, full pressure is available at the needles from the first stroke in the selection range of 0.3 to 4.2 bars, which in turn enables accurate injection volumes from 3 % to 80 %.

The intelligent brine filter system – Underneath the brining good’s conveyor belt, there is a second belt level. Filter belts, that allow the liquid to drip through, drag out impurities into a separate basin. By this, working is possible for many hours without having to change any filter. The conveyor belts are split so that they do not become too heavy for the operator.

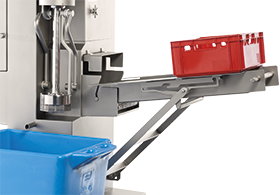

Smart operating aids – An inlet feed ramp set at an angle serves as a chute for tipping in meat. When positioned flat, the ramp can be used as a work surface. For example, bins can be deposited on the surface to feed the meat onto the belt with minimum effort. The machine is built to accommodate standard trolley height, are easily to reach.

- Description

- At one glance

- Technical Specifications

- Single-needle control – As soon as a needle encounters the surface of the meat, the liquid intake opens. If the needle hits bone, the liquid intake closes to prevent too much liquid accumulating at one location. When a needle pierces the meat without meeting bone resistance, it injects until the needle exits the underside of the meat. In this way, the brine is evenly distributed throughout the piece of meat.

- Perfect brine by means of jet pumps – A strong jet leads to perfectly seasoned brine in just one minute. It distributes all the spices and ingredients equally in the water and dissolves them perfectly. A weaker jet maintains the result of mixing during the injection process, keeping the spices and ingredients evenly distributed throughout the curing cycle. As the spices are kept constantly suspended, the meat is uniformly seasoned.

- Softer for greater protein extraction – Fine angled blades cut right through the meat with surgical precision. A suspension system for the blades enables processing of bone-in-meat parts. During the process of cutting through the fibers, the meat structure is softened, activating actomyosin, the meat’s own tenderizer. The result is increased fluid retention and tender meat.

- Touch PC

- Variable operating speeds

- Single – needle control

- Stainless steel immersion / rotary pump

- Softer

- Stainless steel belt

- Welded machine construction

- Standard trolley clearance

- Fold-away workspace

- Machine length: 1.320 – 2.170 mm

- Connected load: 400 V, 8.5 kW, 32 A

- Machine width: 1.321 mm

- Performance: 6.000 kg / h

- Machine height: 1.954 mm

- Machine weight 760 kg

- Pressure: 0.3 – 4.2 bar

Feed inlet height: 280 mm - Rows of needles: 4

- Belt forward feed: 40 / 60 / 80 mm

- Injection rate: 24 / 48 per minute

- Belt width: 720 mm

- Injection volume: 3 – 80 %