Conveyor Systems

Item Ref: WEBB-CON-1234-1

Manufacturing: G-Webb Automation

Condition: New

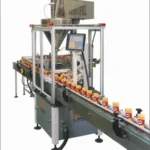

Conveyor Systems For Efficient Filling Solutions

Our in-line conveyor systems are designed to handle and optimize filling operations, offering flexibility from simple setups to fully automated solutions. Whether you need a basic conveyor with a single arrest and fill station or a comprehensive system featuring multiple filling heads, we can deliver. Our filling systems incorporate both volumetric and gravimetric filling, ensuring precision and efficiency at every stage of your production process

Comprehensive Conveyor Systems for Filling Applications

- Container Unscrambling

- Capping

- Labelling

- Collating

A typical system includes a two-meter-long rope conveyor integrated with a weigh-fill station. For instance, the ‘Easifill” auger filler provides an ideal solution for both volumetric and gravimetric filling of composite containers. With speeds of up to 20 fills per minute, these systems handle diverse products with varying characteristics and fill volumes.

- Features

Our conveyor filling systems have a touchscreen operator panel for easy control and parameter adjustments. Each system offers:

- Pre-set product codes for different container types and sizes, optimizing timing and ensuring smooth operation.

- The ability to handle bulk fills and top-ups with line speeds ranging from 20 to 40 containers per minute, depending on product characteristics and fill volume.

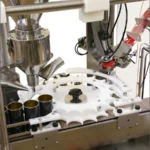

- Systems featuring two or three filling heads for precise operation. The first filler discharges around 70-80% of the fill volumetrically, and the final top-up is managed through the integrated weigh station.