- A sensor on the machine’s hopper controls its throughput, preventing work disruptions caused by products accidentally hanging on the hopper.

- Additional equipment includes a vibration motor for the hopper, which is crucial in maintaining the hopper’s functionality during operation, and a vibration motor for the conveyor belt, which en. Thanks to this, the bag vibrates, and the vegetables are arranged correctly.

- Additional equipment includes a vibration motor for the hopper, which is key to maintaining the hopper’s functionality during operation, and a vibration motor for the conveyor belt, which ensures the filled bag vibrates, arranging the vegetables evenly, a crucial task when packing root vegetables.

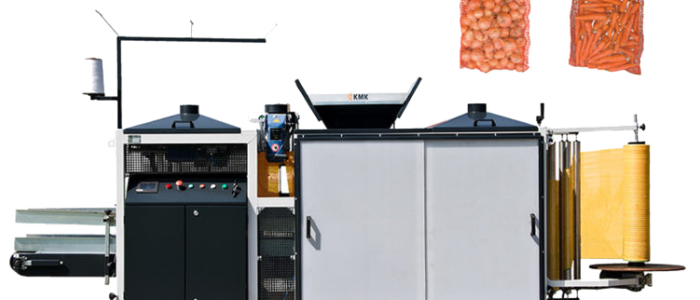

R1/R2 Packaging Machines

Item Ref: KMK-52152-1

Manufacturing: KMK

Condition: New

Model: R1/R2

R1/R2 raschel machines pack potatoes, onions, carrots, parsley, and beets into raschel bags weighing 2.5 kg to 25 kg.

The rasher’s operation principle is to cut the bags wrapped on rolls, fill them with a weighed portion of vegetables and sew them up. The R2 raster has a Fischbein F100 double-thread stitcher, while the R1 raster has a Fischbein/Newlong single-thread stapler.

- Main Feature

- Equipment Elements

- Technical Data

- Construction made of acid-resistant steel

- Vibration motor of the hopper

- Vibrating motor of the conveyor belt

- Thermal transfer printer

- fans

| R1 | R2 | |

| Sewing head | New Long NP-7A/Fischbein F | Fischbein F100 |

| Packaging range | 2.5 kg – 25 kg | 2.5 kg – 25 kg |

| Control | Mitsubishi PLC | Mitsubishi PLC |

| Display | 4.3” | 4.3” |

| Electric power supply | 400V | 400V |

| Pneumatic power supply | 5-6 bar 30 l/min | 5-6 bar 30 l/min |

| Power consumption | 3.2 kW | 3.2 kW |

| Dimensions | 4.4 m x 1.0 m x 2.2 m | 4.4 m x 1.0 m x 2.2 m |

| Net weight | 600 kg | 630 kg |

Have Questions ?

Our team is ready to assist. Please contact us on 09 263 0578 or through our contact form.

Contact Us